- Mobile-Crown High Mast Light Tower

- Fixed Lighting Towers with Ladder and Platform

- Welded Stepped Columns

- Tapered Columns from Steel Sheet

- Octagonal Columns

- Polygonal Columns

- Photovoltaic Panel Columns

- Fence Columns

- Traffic Light Columns

- Columns for Pedestrian Crossing

- Flag Columns

- Cylindric Poles

- Decorative Lighting

- Accessories

- Machining Practicable Poles

- Decorative Lighting Accessories

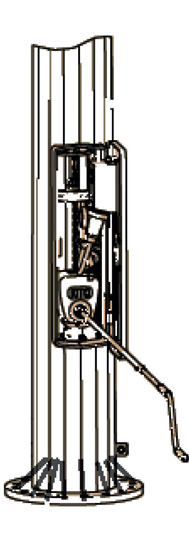

MOBILE-CROWN HIGH MAST LIGHT TOWER

Within the MOBILE-CROWN LIGHTING TOWERS, those which are manuactured by SEIESSE LIGHTING certainly represent highly advanced technical systems,

above all with regard to. SAE MANOEUVRABILITY AND EASE O HANDLING under any conditions thanks to a hinged-type system or coupling and releasing the crown rom the towing unit, which replaces the traditional steel lea spring systems. The mechanical centering o the crown is ensured by the presence o three orks with steel pins that guarantees the insertion accuracy and high resistance to loads by limiting the wear o the mechanical parts.The crown is moved by an electric chain hoist o adequate payload with CE label and connected to three stainless steel ropes placed on the drawing head astened to the top o the tower and connected to the crown through threaded regulation terminals. During the climb and the descent it is provided an anti-rotation system that prevents the movement in the horizontal plane o the crown during the handling. The arms are equipped with five Nylon pulleys (rather than the normal 2), which ensure smoother movements or the stainless steel cables and electrical power cables; this prevents the cables rom being subjected to any stress when the ascent and descent movements are activated. The chain hoist is connected to a connection cylinder, which transmits the movement directly to the ropes and thereby to the movable crown. Inside the base trunk, near the door, it is mounted a limit switch which controls the steps o coupling-release o the movable crown. The engine is equipped with a brake which starts operating in case o a lack o power during handling, by stopping the engine immediately and thus stopping the descent o the movable crown. The movable crown towers are equipped with CE marking in accordance with the Machinery Directive 2006/42 / CE. The label, applied on each pole, reports: code o the tower; serial number: year o construction, electrical characteristics and capacity.

Based on the height o the tower itsel, the mast is composed o two or more tronc-conical shaped sections with polygonal cross-sections which are made rom bent and longitudinally welded sheet steel. The sections are coupled on site by using “Slip on Joint ”. The tower's base section is equipped with lodging or housing the movement mechanisms. The opening is equipped with locking anti- vandal door.

The towing unit, flanged to the top o the tower, consists o three steel monoblock arms welded at 120°, equipped with pulleys in plastic material or the sliding o the hoisting ropes o the movable crown. Depending on the number o oreseen ignitions, each arm may be provided with pulleys or the distribution o electrical cables.

Mast and base langes: S355 steel UNI EN 10025

Structural work: S235JR steel UNI EN 10025

Cables: 2 stainless steel cables o an appropriate cross-section

Sockets, plugs, electrical boxes and electric cables are CE certiied.

All o the steel parts are hot-dip galvanized in accordance with the UNI EN ISO 1461 standard. On demand we can oer an eficient printing service: the color can be chosen among a range o commercial RAL, RAL DESIGN, NCS, PANTONE, BOERO.