SEIESSE LIGHTING S.r.l. is facing an always more demanding and competitive market in terms of quality, service and prices. The company believes that its business outlook depends on its ability to guarantee the agreed quality standards to its customers. Consequently, all of the company’s resources are constantly focused upon ensuring high-quality production.

SEIESSE LIGHTING S.r.l. is facing an always more demanding and competitive market in terms of quality, service and prices. The company believes that its business outlook depends on its ability to guarantee the agreed quality standards to its customers. Consequently, all of the company’s resources are constantly focused upon ensuring high-quality production.

The mission pursued by SEIESSE LIGHTING s.r.l. is to guarantee absolute quality, meant as complete “Customer Satisfaction“.

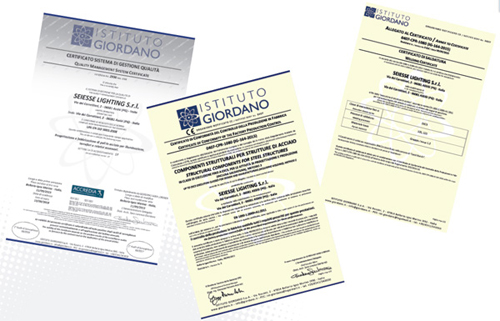

For these reasons, SEIESSE LIGHTING has developed Quality and Environmental Management Systems that comply with the UNI EN ISO 9001:2008 and UNI EN 1090-1.

Seiesse Lighting S.r.l. has been certified to EN 1090-1. This important certification allows us to affix the CE label to every steel structural parts manufactured by our plants.

The CE label is necessary and mandatory to operate on the Italian and European market in order to ensure the quality in terms of technical requirements of the manufactured steel items.

The harmonized Standard EN 1090-1 is effective since July 1st 2014 and it is referred to steel and aluminum structural parts placed on the Italian and European markets. This Standard issues from the European Directive 89/106 / CEE (Construction Products Directive - CPD), which introduced throughout the European Economic Area the commitment to CE Marking for the manufacturing and commercialization of every construction material as well as materials aimed at being permanently incorporated to the assembly. In particular, the Standard EN 1090-1 establishes the requirements for the assessment of conformity on the production audit in the factory of the structural steel and aluminum parts used for the manufacturing of steel structures and steel-concrete mixed, and addresses to every Company, which enters the market for metal structural items.

In order to have the possibility to affix the CE label on its facilities, Seiesse Lighting Srl It has implemented a Control System of the Factory Production Process (FPC), which is a systematic approach to permanent internal control on its production, including Initial Type Testing (ITT / ITC) and additional testing of samples, obtaining a certificate of conformity on the Factory Production Control issued by a Notified Body. Throughout the period of validity of the certificate, the Notified Body held surveillance audits aimed at verifying the maintenance of the system.

In particular, it has been subjected to certification the Welding Process as well, fundamental process for the construction of steel structures.

SEIESSE LIGHTING is entirely dedicated to the customer and has built its own quality system upon three main pillars:

- The Customer as a the main objective behind each company activity

- Collaborators and employees as the Company’s main resource

- The continuous improvement of the Company’s performance with the help of everybody.